Each MTL factory has a R&D team with full-time engineers. The population of technical staff to total employees is 22%, most R&D projects come from the market demand and are self-selected according to industry development. On average 3-5 new and special products per month are developed according to the market needs, and introduced to customer timely. In the process of technological development, the overcoming challenges gradually promote technological accumulation of MTL. Sufficient resources of special material and special production methods are provided for researching. The establishment of MTL R&D Center and MTL Technology Committee contribute to the technology innovation.

Quality Technology Center

Overall planning the internal quality and technical roadmap, and standards.

Engineering production center

A technical team of nearly 200 people with capability of supporting 300 projects per day.

R&D center

A professional R&D team with nearly 50 patents through internal development.

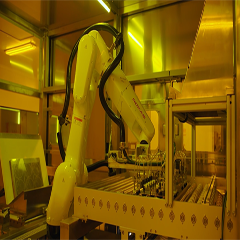

Automated Guided Vehicle System

Laser drilling machine

Verify repair system after resin plugging

Major Equipment

Vacuum etching line

Automatic board transfer system

CNC routing machine

MTL is deeply involved in prototype, small to medium volume, and special board fabrication with good delivery performance.

20000 ㎡

Monthly production capacity

20000 projects

Monthly project quantities

Sample production

Lead time

Double sided

4 days

4 Layers

5 days

6 Layers

6 days

8 Layers

7 days

10 Layers

8-10 days

Batch Production

Lead time

Small batch production

5-10 days

Medium batch production

8-24 days

Expedited service

The fastest delivery time is 24 hours for sample orders.

ltems

Sample capabilities

Small/Medium batch capabilities

Layer count

1-108L

1-46L

Finish board thickness

0.2mm - 10.0mm

0.4mm - 6.0mm

Max panel size

610mm * 1200mm

610mm * 1200mm

Finish copper thickness

0.5OZ - 12OZ

0.5OZ - 6OZ

Min line width/space

2.5mil / 2.5mil

3mil / 3mil

Min finish hole size

0.1mm

0.15mm

Max aspect ratio

25:1

12:1

Impedance control tolerance

+/-10%

+/-10%

Surface finishes: HASL (LF), ENlG, lmmersion Tin, lmmersion silver, Golden finger, Full board with hard gold plating, OSP, ENEPlG, Selective hard gold plating.

Regular materials:: ? FR-4 TG150/TG170, Rogers, Arlon, Taconic, TUC TU-872 SLK, TU-883,Panasonic M6/M7, Bergguist etc.

Special technologies: Blind & buried vias, POFV, edge plating, castellated holes, step mounting holes, controlled depth holes, metal based (core), step gold finger, back drill,partial hybrid pressing, bus bar,embedded coin, embedded ceramic etc.

★ Strictly in accordance with the quality management system and develop the awareness of making each PCB with superior quality.

★ Do it right the first time.

★ People of involvement and total process control.

★ Target and confidence in 100% quality assurance

★ Acceptance standard: Customer requirements, IPC standard, GJB362

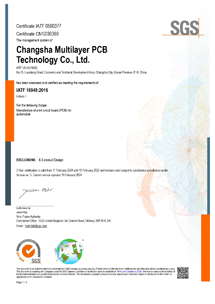

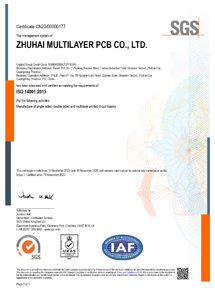

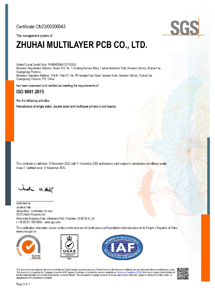

Quality system

Based on ISO 9001 quality system,

and synchronous operation with IATF16949.

1

Acceptance standard

Regular standard: IPC class 2 Special standard: IPC class 3

Customized standard: GJB362B

2

Quality control

Whole Process Quality Control

3

Quality Improvement Services

Assist customers to formulate quality standards.

Cooperate with customer on experiments to enhance product performance.

4

Laboratory Capabilities

5